Features

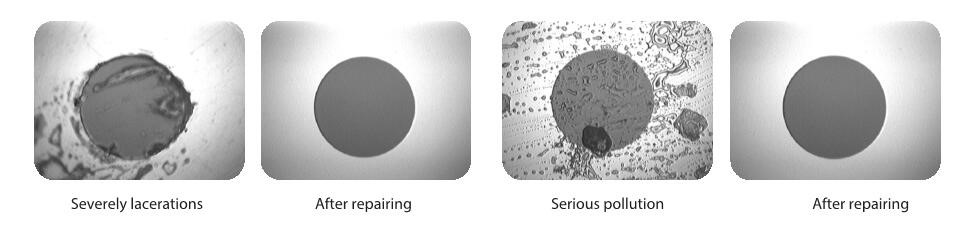

It is very suitable for repairing the chippings, serious scratches and serious pollution of the fiber jumper ending.

* It is suitable for fiber ending of FC/PC, SC/PC, LC/PC.

* Easy carrying battery powered can use in the filed Handy- carrying case, dry battery.

* The time of repairing is 1-3 min. Polishing time: approx 3min

* Stable Packing

* Save Time and cost

Polishing Process

Install the optical connectro on the grinding tool

* Turn on the power and lamp lights.

* Adjust the speed and time of grinding.

* Push the key of “ON/OFF”, this machine will start working automatically.

* When the schedule time arrives , the machine will stop working a automatically.

Background

Any Contamination such as dust particles, oil and other residues could cause an air gap or misalignment between fiber cores. Therefore it may block and degrade the optical signal. The martin Technical Research Company took this into research, that 8% user and 90% telecom operators have this problem caused by dirty endface of fiber optic connector. On the other hand, 72% user and 89& telecom operator have suffered the problem that made by bad polishing. This index is much higher than other failures caused by other operators.

Technical Specification:

| Internet User | Reasons Of Fiber Error | Telecom Operators |

| 80% | Pollution Of Terminal Junction | 98% |

| 72% | Bad Polishing | 88% |

| 40% | Connector Open | 86% |

| 8% | Wrong Signage | 86% |

| 34% | he Surface Of Terminal Junction Damage | 82% |

| 36% | Adverse Weld | 74% |

| 6% | Bending | 66% |

Especially the local area, there are so many fiber and communication equipment. During the operation, there are always some impressive problem such as dust, oil and other residues, which may degrade the optical signal.

Reviews

There are no reviews yet.